When sourcing Personal Protective Equipment (PPE) for your workforce, compliance isn’t just a feature—it’s a legal and ethical necessity. For industrial footwear, understanding the complex web of safety standards is the first step to ensuring your team is properly protected. This guide will demystify the key U.S. safety shoe standards, focusing on ANSI and the current ASTM requirements. Knowing these standards is crucial for every procurement manager. For compliant and reliable safety shoe solutions, you can rely on our expertise.

The Evolution of Standards: From ANSI Z41 to ASTM F2413

To understand today’s standards, it helps to know where they came from. You might still see references to both ANSI and ASTM.

Understanding the Legacy ANSI Z41 Standard

For many years, the ANSI Z41 standard was the primary benchmark for safety footwear in the United States. It established the criteria for testing and performance. While this standard is now obsolete, you may occasionally see it referenced on older equipment or documentation.

Why ASTM F2413 is the Current U.S. Standard

In 2005, the responsibility for this standard was transferred to the American Society for Testing and Materials (ASTM). What is ASTM F2413? It is the current standard specification for Performance Requirements for Protective (Safety) Toe Cap Footwear. All safety footwear sold in the U.S. must meet or exceed this benchmark.

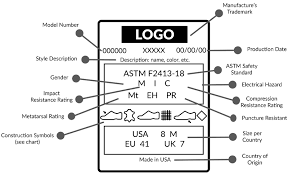

Decoding the ASTM F2413 Label: What Each Code Means

Every pair of compliant safety shoes has a label inside that looks like a line of code. This is your key to understanding its specific protections. What do the codes on a safety shoe label mean? Here’s a breakdown:

A typical label might read: ASTM F2413-18 M/I/75/C/75/PR/EH

I/75 and C/75: Impact and Compression Resistance Explained

- I/75: This indicates the shoe meets the standard for Impact Resistance. The “75” means the toe cap can withstand an impact of 75 foot-pounds.

- C/75: This indicates the shoe meets the standard for Compression Resistance. The “75” means it can withstand a compressive load of 2,500 pounds before the toe cap begins to crush.

PR: Puncture Resistance for Underfoot Protection

If you see “PR” on the label, it means the shoe has a puncture-resistant plate in the midsole. This plate is designed to protect the foot from sharp objects like nails or scrap metal from below.

EH: Electrical Hazard Protection

EH-rated footwear is designed to protect the wearer from open electrical circuits of up to 18,000 volts. The soles are made to reduce the potential for electric shock. This is crucial for electricians and maintenance workers.

SD: Static Dissipative Properties

SD footwear is designed to reduce the buildup of static electricity. This is essential in environments where a static discharge could damage sensitive electronic equipment or ignite flammable materials.

Key Protective Features to Look for in Industrial Footwear

The standards are met through specific design features and materials. Here are the most important ones in industrial footwear.

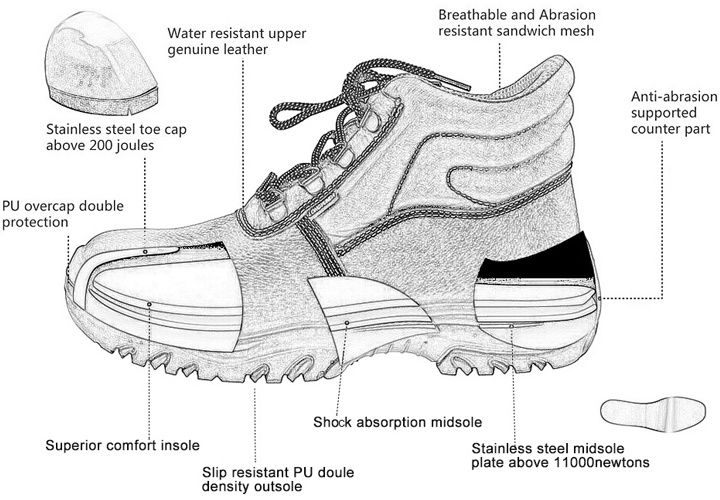

Steel, Composite, and Alloy Toe Caps: A Comparison

- Steel Toe: The traditional choice, offering maximum protection.

- Composite Toe: Made from materials like carbon fiber or plastic, these are lighter than steel and do not conduct electricity.

- Alloy Toe: Lighter than steel but just as strong, often made from aluminum or titanium.

Puncture-Resistant Midsoles: Steel vs. Non-Metallic Options

The puncture-resistant plate can be a steel plate or a flexible, non-metallic fabric like Kevlar. Non-metallic options offer more flexibility and do not conduct heat or cold.

Slip-Resistant Outsoles: A Critical Safety Feature

While not always part of the main ASTM code, slip-resistant outsoles are one of the most important safety features. Look for outsoles with a tread pattern and material compound designed to provide grip on wet or oily surfaces.

Beyond the Standards: Ensuring Quality in Your Safety Shoe Manufacturing

Compliance is the minimum. A true manufacturing partner ensures that quality is built into every pair.

The Importance of Quality Materials and Construction

Meeting a standard once in a lab is different from producing thousands of consistently high-quality pairs. This requires durable leathers, strong bonding, and robust stitching that can withstand the rigors of the workplace.

How We Ensure Every Pair Meets or Exceeds the Standard

At BMLineColl.com, we combine a deep understanding of safety shoe standards with a rigorous, multi-stage QA process. Our on-site teams ensure that every component and every assembly step is checked, guaranteeing that the final product is not only compliant but also durable and comfortable.

Compliance is the First Step to a Safer Workplace

Choosing the right safety footwear is a critical responsibility. By understanding the ASTM F2413 standard and the technology behind it, you can make an informed decision that protects your team and your business. It’s the first and most important step toward creating a culture of safety.

Need to source high-quality, fully compliant safety footwear for your team? Contact our industrial footwear experts to ensure every step your employees take is a safe one.

Frequently Asked Questions About Safety Shoe Compliance

Are European (EN ISO 20345) and ASTM standards interchangeable?

Are European and ASTM standards interchangeable? No, they are not directly interchangeable. While they often test for similar hazards, the testing methods and classification levels can differ. If you are selling or operating in the U.S., you must ensure your footwear meets ASTM F2413. If in Europe, it must meet EN ISO 20345.

How often should safety shoes be replaced?

How often should safety shoes be replaced? There is no single rule, but they should be replaced immediately after any major incident (e.g., a heavy object falling on the toe). Otherwise, replace them when they show visible signs of wear and tear, such as cracked soles or exposed toe caps. A general guideline is every 6-12 months for heavy use.

Do I need to provide certification for my employees’ safety shoes?

Do I need to provide certification for employees’ safety shoes? As an employer, you are responsible for ensuring the PPE you provide is compliant. You should keep records from the manufacturer or supplier, like us at BMLineColl.com, confirming that the footwear meets the required ASTM standard for your workplace’s specific hazards.