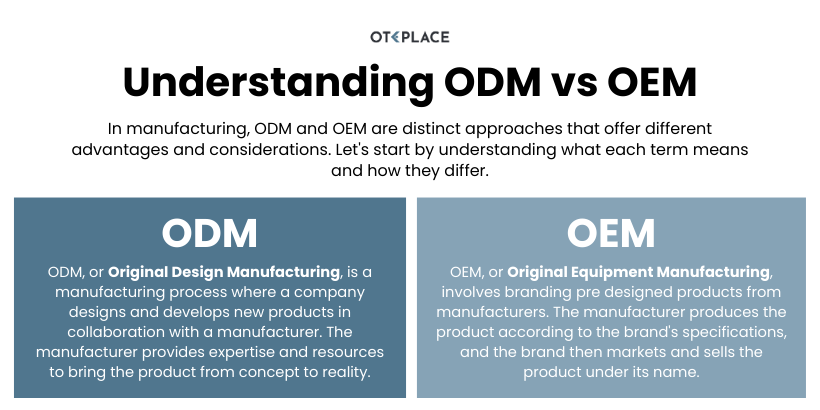

When launching or expanding a product line, one of the first strategic decisions you’ll face is choosing the right manufacturing model. You’ll frequently encounter two acronyms: OEM and ODM. What is the difference between OEM and ODM? Making the right choice between them can significantly impact your product’s uniqueness, your budget, and your speed to market. This guide will provide a clear breakdown of the OEM vs ODM models to help you decide the best path for your custom shoes or bags.

What is OEM (Original Equipment Manufacturer)?

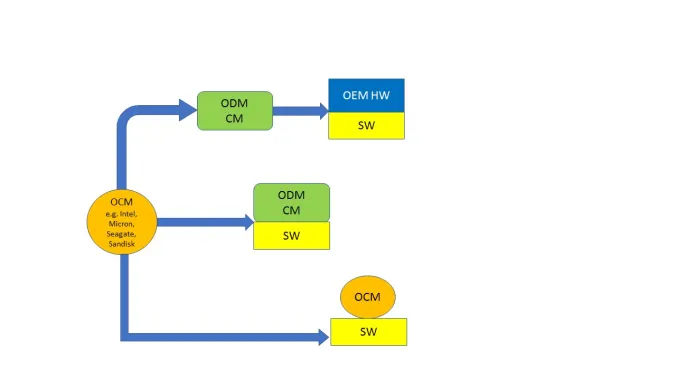

OEM, or Original Equipment Manufacturer, is a model where a factory produces goods based on the designs and specifications provided by you, the client.

The Process: Your Design, Our Manufacturing Expertise

In an OEM manufacturing partnership, you are responsible for the research, development, and design of the product. You provide a detailed technical pack (Tech Pack), and the manufacturer uses its equipment, materials, and labor to bring your unique vision to life.

Pros of Choosing the OEM Path (e.g., Full Control, IP Ownership)

- Full Control: You have complete control over the design, materials, and every detail of the product.

- IP Ownership: You own the intellectual property (IP) of your unique design, creating a competitive advantage.

- Brand Uniqueness: Your product is 100% unique to your brand.

Cons of Choosing the OEM Path (e.g., Higher R&D Investment)

- Higher R&D Investment: You bear the full cost and time commitment of research and development.

- Longer Time-to-Market: The design, prototyping, and testing phases can be lengthy.

- Requires Design Expertise: You need to have in-house or contracted design capabilities.

What is ODM (Original Design Manufacturer)?

ODM, or Original Design Manufacturer, is a model where you select a pre-existing product design from the manufacturer’s catalog and sell it under your own brand name.

The Process: Our Design, Your Brand

In an ODM partnership, the manufacturer has already handled the R&D, design, and tooling for a range of products. You simply choose a design, often with options for minor modifications (like colors or logos), and apply your branding. This is often referred to as private label.

Pros of Choosing the ODM Path (e.g., Faster Time-to-Market, Lower R&D Costs)

- Faster Time-to-Market: Since the design is already complete, you can launch a new product very quickly.

- Lower R&D Costs: You save significantly on design, development, and tooling costs.

- Proven Designs: You are often choosing from designs that have already been tested and are production-ready.

Cons of Choosing the ODM Path (e.g., Less Design Uniqueness)

- Less Design Uniqueness: Other brands may be selling the same or a very similar product.

- Limited Customization: Your ability to alter the core design is usually restricted.

- No IP Ownership: The manufacturer owns the rights to the product’s design.

At a Glance: OEM vs ODM Direct Comparison Table

To make the choice clearer, here is a direct comparison of the two models.

Key Differences: Design, IP, Cost, Speed, and More

| Feature | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

| Design Origin | Provided by the Client (You) | Provided by the Manufacturer |

| Intellectual Property | Owned by the Client (You) | Owned by the Manufacturer |

| R&D Investment | High | Low to None |

| Time-to-Market | Slower | Faster |

| Product Uniqueness | High | Low |

| Best For | Brands with unique, proprietary designs | Brands wanting to launch quickly or test markets |

How to Choose: A Decision-Making Framework for Your Brand

Which is better OEM or ODM? The answer depends entirely on your brand’s strategy, resources, and goals.

Choose OEM if…

You should choose the OEM path if you have a unique, innovative design that is central to your brand’s identity, and you have the resources (time and money) to invest in R&D. This path is for building a brand with a strong, defensible product advantage.

Choose ODM if…

You should choose the ODM path if your priority is speed, you want to test a new market with minimal risk, or if your brand’s strength lies in marketing and distribution rather than product design. It’s an excellent way to quickly build out a product catalog.

Can You Use a Hybrid Approach?

Yes. Some brands use a hybrid approach. They might start with ODM products to build cash flow and market presence, then invest those earnings into developing their own unique OEM products later.

How BMLineColl Excels in Both OEM and ODM Services

Whether you’re a visionary designer or a savvy marketer, we have the expertise to support your goals. Our one-stop service is designed to be flexible.

Our Commitment to Your Vision in OEM Projects

For our OEM partners, we act as a dedicated manufacturing arm. We respect your vision and intellectual property, using our 18 years of experience to execute your designs to the highest standard.

Our Innovative Designs for Your Private Label ODM Needs

For our ODM partners, we offer a curated selection of market-ready designs. We can help you quickly launch a high-quality private label collection, allowing you to focus on building your brand. Explore our capabilities today.

The Right Model for a Stronger Brand Foundation

Choosing between OEM and ODM is a foundational decision for your brand. By understanding the trade-offs between control, speed, and investment, you can select the model that best aligns with your long-term vision and sets you up for success.

Whether you’re ready with a full tech pack (OEM) or looking to leverage our designs (ODM), we have a solution. Contact our experts at BMLineColl.com to discuss your brand’s strategic manufacturing needs.

Frequently Asked Questions About OEM and ODM

Can I modify an ODM product?

Can I modify an ODM product? Yes, to an extent. Most ODM manufacturers allow for minor modifications, known as “private labeling.” This typically includes changing colors, materials, logos, and packaging. However, fundamental changes to the product’s structure or mold are usually not possible.

Who owns the tooling (molds) in an OEM vs ODM project?

Who owns the tooling (molds) in an OEM vs ODM project? In a true OEM project, the client pays for the custom tooling, and therefore owns it. In an ODM project, the manufacturer owns the tooling, as they developed the product before you came along.

Is one model cheaper than the other?

Is one model cheaper than the other? The ODM model has a lower upfront cost because you are not paying for R&D and tooling. However, the per-unit cost of an OEM product might be lower in the long run if you produce in very high volumes, as you are not paying a premium for the manufacturer’s design work. Get a detailed quote for your project to compare.