For any brand, product quality is the bedrock of its reputation. A great design and competitive pricing mean nothing if the final product fails to meet customer expectations. This raises the most important question for any procurement manager: How do you ensure product quality consistently across thousands of units? At BMLineColl, we believe quality isn’t a final check; it’s a systematic process embedded in every stage of manufacturing. This article offers a transparent look into our robust Quality Assurance Process. Discover a partnership built on trust and quality.

The Foundation: Proactive Supplier Quality Control

Effective quality management starts long before the first stitch is made. Our approach is proactive, focusing on prevention rather than reaction. This foundational stage of supplier quality control is designed to eliminate problems at their source.

Stage 1: Pre-Production Material Testing

The quality of a finished product is only as good as the raw materials used. Our process begins with rigorous material testing. Before any production run, our teams test all incoming fabrics, soles, zippers, and other components to ensure they meet the agreed-upon specifications for durability, colorfastness, and performance.

Stage 2: Analyzing Potential Risks Before Production

With 18 years of experience, we’ve learned to anticipate challenges. For each new design, our experts analyze potential risks during the manufacturing process. This could involve complex stitching, delicate materials, or intricate assembly steps.

Stage 3: Creating a Preventive Action Plan

Based on the risk analysis, we develop a preventive plan. This plan outlines specific checkpoints, machine settings, and handling procedures to mitigate identified risks, ensuring the production line runs smoothly and efficiently from day one.

The Core of Our Process: The Co-located QA Team

This is what truly sets our quality assurance apart. What is a QA team? For us, it’s your dedicated team of experts on the ground, ensuring standards are met every single day.

Why a QA Team on the Factory Floor is a Game-Changer

Instead of relying solely on end-of-line inspections, we have a co-located QA team in every factory we partner with. This means our quality experts are present on the factory floor, overseeing the entire production process directly.

Real-Time Monitoring and Immediate Intervention

Our on-site QA team conducts real-time monitoring. If any deviation from the standard is detected, they can intervene immediately to correct the issue. This prevents small errors from becoming large-scale quality problems, saving time and resources.

Your Eyes and Ears Throughout the Production Cycle

This team acts as your representative, ensuring that your standards are upheld throughout the manufacturing journey. It’s a level of transparency and control that provides complete peace of mind.

Multi-Stage Inspections for Consistent Results

A single final check is not enough. Our Quality Assurance Process involves multiple inspection points to guarantee consistency.

In-Process Quality Control (IPQC) Checks

During production, our teams perform regular IPQC checks at critical assembly stages. This ensures that each component is being attached, stitched, or formed correctly before the product moves to the next phase.

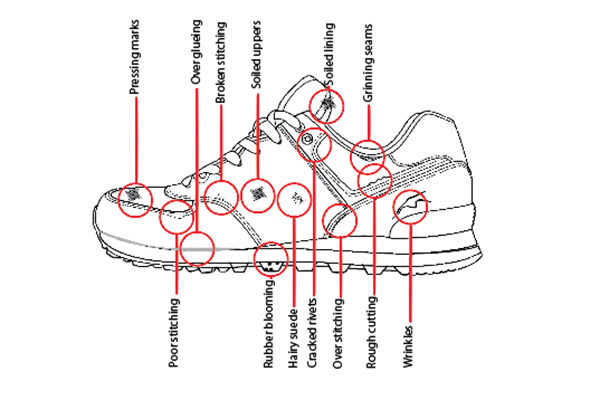

Final Product Inspection Before Packing

Once a product is fully assembled, it undergoes a comprehensive final product inspection. We check against a detailed list of specifications, from dimensions and aesthetics to functionality and durability, before it is approved for packing.

Adhering to Your Brand’s Specific Quality Standards

We understand that every brand has unique requirements. We work closely with you to integrate your specific quality standards and checklists into our inspection process, ensuring the final product is a perfect reflection of your brand’s promise.

Beyond Production: Our Commitment to Continuous Improvement

Our commitment to quality doesn’t end when an order ships. We believe in continuous improvement to refine our processes and deliver even better results for our partners.

Gathering Feedback and Analyzing Order Data

We actively gather feedback from our clients and analyze production data from every order. This information helps us identify areas for improvement in our processes and with our factory partners.

Training and Development for Our QA Professionals

Our QA professionals undergo regular training to stay updated on the latest quality control techniques, international standards, and new material technologies. This ensures our team remains at the forefront of the industry.

Quality Isn’t an Accident; It’s Our Process

Ultimately, the ability to ensure product quality comes down to having a robust, transparent, and proactive system. It’s about building quality into every step, from the initial raw material to the final stitch. This meticulous process is our promise to you and the foundation of a successful, long-term partnership.

Ready to experience a sourcing process where quality is guaranteed? Contact our expert team at BMLineColl.com today.

Frequently Asked Questions About Our Quality Assurance

Can I provide my own quality inspection checklist?

Can I provide my own quality inspection checklist? Yes, absolutely. We encourage our clients to provide their specific checklists and quality standards. Our QA team will integrate your requirements into our inspection process to ensure the products meet your exact expectations.

Do you work with third-party inspection services like SGS or Intertek?

Do you work with third-party inspection services? While our internal co-located QA team provides comprehensive oversight, we fully support and can coordinate with any third-party inspection service you choose to hire for an additional layer of verification.

How do you handle products that don’t meet the quality standards?

How do you handle products that don’t meet quality standards? Thanks to our real-time monitoring, most issues are caught and corrected during production. Any items that fail the final inspection are immediately quarantined, and we will rework or reproduce them to meet the standard before shipment, ensuring you only receive products that pass our rigorous checks. Our commitment is to deliver what we promised.