A cooler bag is a marvel of portable science, acting as a personal, flexible refrigerator. But have you ever wondered about the specifics? How do cooler bags work? It’s not magic; it’s a carefully engineered system of materials designed to combat heat. Understanding this cooler bag technology is key for any brand looking to source high-quality thermal bags. This guide will break down the science of insulation, from the outer shell to the inner lining. For expertly crafted custom cooler bags, understanding this process is the first step.

The Science of Insulation: How Thermal Bags Keep Things Cool

To understand how cooler bags work, we first need to understand their enemy: heat.

Understanding the Three Types of Heat Transfer

Heat moves in three ways: conduction (through direct contact), convection (through the movement of air or liquid), and radiation (through electromagnetic waves). A good cooler bag is designed to slow down all three types of heat transfer.

How Insulation Works to Slow Down Heat Transfer

The core principle of insulation is to create a barrier that is a poor conductor of heat. By trapping air within a material, insulation drastically reduces the rate at which outside heat can warm up the inside of the bag.

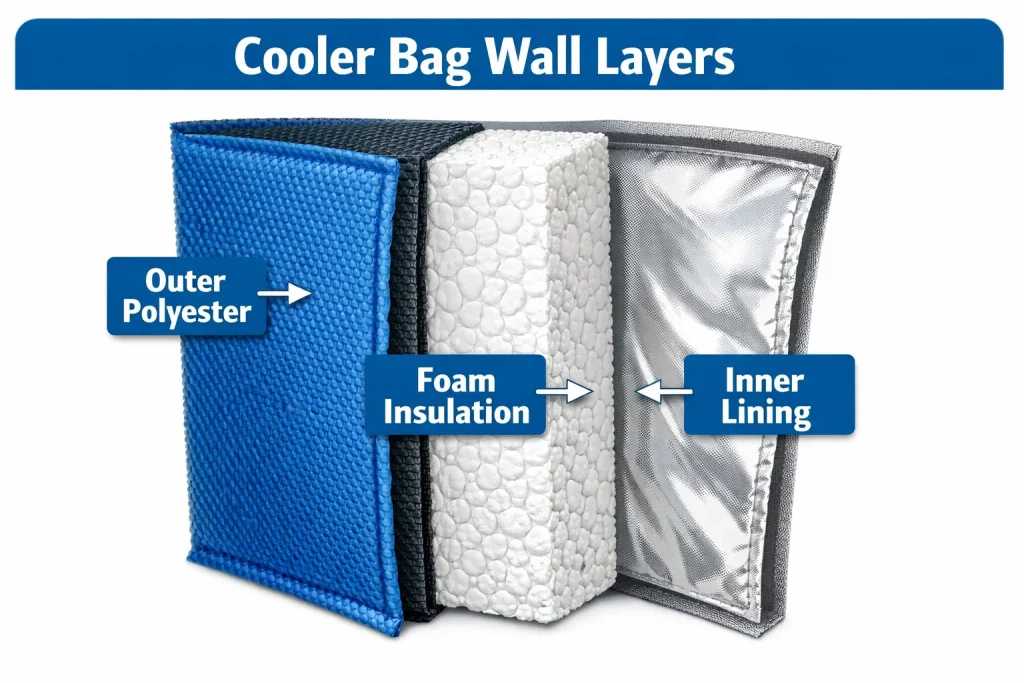

The Anatomy of a Cooler Bag: A Layer-by-Layer Breakdown

A high-performance cooler bag is constructed with three distinct layers, each playing a critical role.

Layer 1: The Outer Fabric (e.g., Polyester, Nylon)

The exterior layer provides durability and structure. It’s typically made from a robust material like polyester or nylon, which can withstand wear and tear. This layer’s primary job is to protect the inner components.

Layer 2: The Insulation Core (Foam is Key)

This is the heart of the cooler bag’s performance. The core insulation material is almost always a layer of closed-cell foam. This foam insulation is effective because it’s filled with tiny pockets of trapped air, which are excellent at preventing heat conduction.

Layer 3: The Waterproof Inner Lining

The inner lining has two jobs: to be a final barrier against heat and, crucially, to contain any spills or condensation. A waterproof inner lining is essential to prevent messy leaks and make cleaning easy.

The Inner Lining Showdown: PEVA vs. PVC and Aluminum Foil

The choice of inner lining material is critical for safety, performance, and environmental impact.

What is PEVA Material and Why is it a Superior Choice? (Food-Safe, Eco-Friendlier)

What is PEVA material? PEVA (Polyethylene vinyl acetate) is a non-chlorinated vinyl. It has become the gold standard for cooler bag linings for two main reasons:

- Food-Safe: It is phthalate-free and BPA-free, making it a safe choice for direct contact with food.

- Eco-Friendlier: It is a more environmentally friendly alternative to PVC. This makes PEVA material the responsible choice for modern brands.

The Problem with PVC Linings

PVC (Polyvinyl chloride) was once common, but it often contains chlorine and plasticizers like phthalates, which have raised health and environmental concerns. Most reputable manufacturers have moved away from PVC in food-contact products.

The Role of Reflective Aluminum Foil Linings

Some cooler bags use a reflective foil lining. This helps to combat radiant heat transfer, reflecting thermal energy away from the contents. It’s often laminated onto another material like PEVA for structure and waterproofing.

Beyond Materials: Construction Details That Matter

Even the best materials will fail if the bag is poorly constructed. Two details are particularly important.

The Importance of Heat-Sealed, Leak-Proof Seams

Instead of being stitched (which creates tiny holes), the seams of a high-quality cooler bag’s inner lining should be heat-sealed. This welding process creates a continuous, leak-proof bond, ensuring that melted ice or spills are fully contained.

How Zipper Quality Affects Thermal Performance

Zippers are a major source of heat entry. While standard zippers are fine for casual use, high-performance cooler bags may use water-resistant zippers or have insulated zipper baffles to minimize air exchange and improve thermal efficiency.

Choosing the Right Cooler Bag for Your Promotional Needs

Understanding this technology allows you to source a product that truly delivers value.

How High-Performance Features Increase Perceived Value

A cooler bag with a food-safe PEVA lining and leak-proof seams has a much higher perceived value than a basic one. It’s a premium corporate gift that shows you care about quality and safety.

Our Expertise in Customizing Functional Cooler Bags

At BMLineColl.com, we specialize in creating functional bags that perform. We can guide you through the material and construction options to build custom cooler bags that perfectly represent your brand’s commitment to quality.

It’s Not Just a Bag, It’s a Thermal System

A cooler bag is a sophisticated thermal system where every layer and every seam plays a role. By choosing superior materials like PEVA and insisting on quality construction like heat-sealed seams, you can offer a product that delivers real, measurable performance.

Ready to create a high-performance cooler bag that elevates your brand? Speak with our technical experts at BMLineColl.com.

Frequently Asked Questions About Cooler Bag Technology

How long can a good cooler bag keep items cold?

How long can a good cooler bag keep items cold? This depends on the thickness of the foam insulation, the quality of the seals, and external conditions. A well-made soft cooler bag can typically keep items cold for anywhere from 4 to 12 hours, especially when used with ice packs.

Can cooler bags also be used to keep food warm?

Can cooler bags also be used to keep food warm? Yes. The same insulation that slows down heat from entering the bag also slows down heat from escaping. They are excellent for transporting hot dishes to a picnic or party.

Is PEVA lining easy to clean?

Is PEVA lining easy to clean? Yes, it’s one of its best features. The smooth, waterproof surface of a PEVA material lining is very easy to wipe clean with a damp cloth, making it hygienic and convenient for everyday use. To learn more about our material options, contact our team.