Stepping into the world of product manufacturing can feel like learning a new language. Acronyms and industry-specific terms are everywhere, and clear communication is the key to a successful partnership. To help you navigate your sourcing journey with confidence, we’ve compiled the ultimate manufacturing glossary. This guide decodes the essential shoe terminology and bag industry vocabulary you need to know. Understanding these sourcing terms will empower you to speak the same language as your supplier. Let’s start your professional sourcing conversation today.

Core Business Models and Partnership Terms

These terms define the nature of your relationship with a manufacturer.

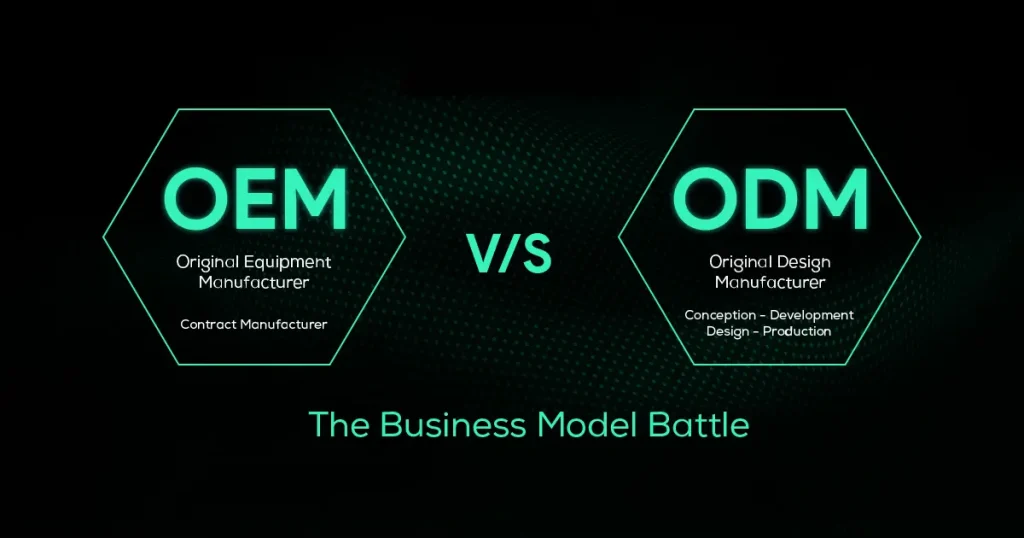

OEM (Original Equipment Manufacturer)

OEM is a partnership where the factory produces goods based on your unique design and specifications. You provide the tech pack, and they handle the production. This model gives you full control over your product’s design and intellectual property.

ODM (Original Design Manufacturer)

ODM is a model where you select a pre-existing design from a manufacturer’s catalog and apply your own branding (private label). It’s a faster and more cost-effective way to launch a product, as the R&D has already been done by the factory.

MOQ (Minimum Order Quantity)

What does MOQ mean? This is the minimum number of units a factory is willing to produce in a single production run. It’s determined by factors like material procurement costs and production line efficiency.

The Product Development & Design Glossary

These terms are the building blocks of turning your idea into a physical product.

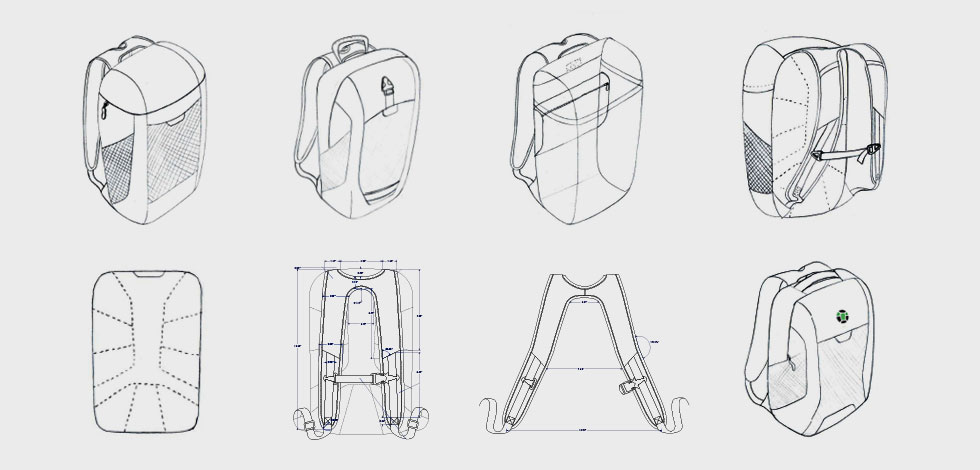

Tech Pack (Technical Pack)

What is a tech pack in fashion? The Tech Pack is the single most important document in product development. It’s a detailed blueprint containing all specifications, including technical drawings, materials, colors, construction details, and measurements.

BOM (Bill of Materials)

Part of the Tech Pack, the BOM is a comprehensive list of every single component and raw material required to build your product, from the main fabric down to the thread and eyelets.

Prototype / Sample

A prototype or sample is a preliminary version of your product created for testing and evaluation. Approving the final sample is a critical step before starting mass production.

Tooling / Mold

Tooling or molds are custom-made components required to produce specific parts of your shoe, most commonly the outsole. The cost of creating new molds is a significant factor in product development.

Essential Material Terminology for Bags and Shoes

Understanding materials is key to defining your product’s quality, performance, and cost.

EVA (Ethylene-Vinyl Acetate)

EVA is a lightweight, foam-like material prized for its excellent cushioning. It is most commonly used for the midsoles of athletic shoes.

TPR (Thermoplastic Rubber)

TPR is a blend of plastic and rubber. It offers a good balance of durability, slip resistance, and cost, making it a popular choice for the outsoles of casual footwear.

PU (Polyurethane) Leather

PU leather is a synthetic leather alternative made from polyurethane. It’s a versatile and cost-effective material used widely for shoe uppers and bag exteriors.

Nylon / Polyester

These are two of the most common synthetic fabrics used for backpacks and the uppers of sports shoes. They are known for their durability, light weight, and resistance to abrasion.

Denier

Denier (D) is a unit of measurement for the thickness or density of a fiber. A higher denier number (e.g., 1000D Nylon) indicates a thicker, heavier, and generally more durable fabric.

Logistics and International Trade Terms (Incoterms)

These terms define the responsibilities for shipping and logistics.

FOB (Free On Board)

FOB is a common Incoterm where the seller’s responsibility ends once the goods are loaded onto the shipping vessel at a named port. The buyer is then responsible for the sea freight, insurance, and import procedures.

EXW (Ex Works)

Under EXW, the seller’s only responsibility is to make the goods available at their factory. The buyer must manage the entire shipping process, including export and import.

Lead Time

Lead Time is the total time required from placing a purchase order to receiving the finished goods. It includes material sourcing, production, and shipping time.

Quality Control and Manufacturing Vocabulary

These terms are crucial for ensuring your product meets your standards.

QA (Quality Assurance)

QA is a proactive process focused on preventing defects. It involves setting up systems and standards to ensure quality is built into every step of the manufacturing process.

QC (Quality Control)

QC is a reactive process focused on identifying defects. It involves the inspection and testing of products to ensure they meet the pre-defined quality standards.

IPQC (In-Process Quality Control)

IPQC refers to quality checks that are performed during the manufacturing process, not just at the end. This allows for the early detection and correction of any issues.

Speak the Language of Manufacturing for a Smoother Sourcing Journey

Mastering this vocabulary is the first step toward building a strong, transparent, and efficient relationship with your manufacturing partner. When you and your supplier speak the same language, you minimize misunderstandings and pave the way for a successful production run.

Now that you’re equipped with the essential terminology, are you ready for a professional conversation? Contact our expert team at BMLineColl.com; we understand and can execute your every professional requirement.

Frequently Asked Questions About Industry Terms

What’s the most important term for a new brand to understand?

What’s the most important term for a new brand to understand? Arguably, it’s a tie between MOQ and Tech Pack. Understanding your MOQ limitations is crucial for financial planning, while a detailed Tech Pack is the foundation for getting the product you actually want.

Why are Incoterms so important in a contract?

Why are Incoterms so important? They are legally binding terms that clearly define who is responsible for costs and risks at every stage of the shipping process. Using them correctly prevents costly disputes and ensures both the buyer and seller know their exact obligations.

What is the difference between QA and QC?

What is the difference between QA and QC? Think of it this way: Quality Assurance (QA) is the overall strategy and system you create to prevent defects (e.g., training workers, setting standards). Quality Control (QC) is the act of inspecting the products to find any defects that may have occurred. A great supplier, like BMLineColl.com, excels at both.